Top 10 UL FM Gate Valve Solutions: Ultimate Guide for Fire Safety Compliance and Efficiency

2025-12-23

When it comes to fire safety compliance and efficiency, UL FM gate valves are a critical component that can make all the difference in protecting lives and property. In this ultimate guide, we explore the top 10 solutions to help you navigate the complexities of fire safety systems with confidence. Whether you're an engineer, facility manager, or safety professional, understanding these valves is key to ensuring robust protection. At DRIFCO, we're dedicated to providing insights that not only meet standards but exceed expectations. Dive in to discover how these innovative solutions can enhance your fire safety strategy and keep your operations running smoothly.

Exploring the Fundamentals of UL FM Gate Valve Design for Fire Safety

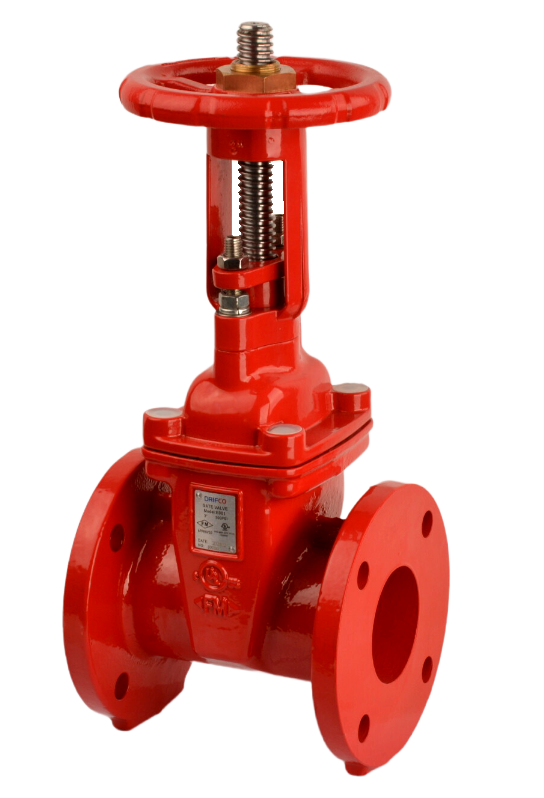

UL FM gate valves play a crucial role in fire protection systems, designed to ensure reliable shut-off during emergencies. These valves are engineered with features like robust construction and smooth operation to withstand high pressures and temperatures, preventing leaks that could compromise fire safety. By meeting stringent UL and FM standards, they provide assurance in critical applications, from industrial facilities to commercial buildings, where quick response and durability are non-negotiable.

Key design elements focus on materials and sealing mechanisms, often utilizing corrosion-resistant alloys and tight-seat designs to resist wear over time. Unlike standard valves, UL FM gate valves undergo rigorous testing for performance under fire conditions, including endurance cycles and pressure surges. This ensures they remain functional even in harsh environments, contributing to overall system resilience and compliance with safety codes that prioritize life and property protection.

Innovations in these valve designs emphasize ease of maintenance and integration with modern fire safety technologies. By incorporating features like visual indicators for valve position and compatibility with automated monitoring systems, they enhance operational efficiency and reduce downtime. Ultimately, understanding these fundamentals helps engineers and specifiers select the right valves to create robust fire safety infrastructures that stand the test of time and emergencies.

Key Features That Enhance Efficiency in UL FM Gate Valve Installations

When it comes to UL FM gate valve installations, several key features streamline the process significantly. The robust design of these valves reduces the need for extensive on-site adjustments, allowing installers to secure them quickly in various settings. Additionally, their compatibility with standard tools and fasteners means teams can avoid custom fabrication, saving hours of labor. This efficiency translates directly into lower project costs and faster completion times, making them a go-to choice for time-sensitive applications.

Another standout aspect is the integrated ease-of-maintenance features. Many UL FM gate valves are engineered with accessible components that simplify inspections and repairs without full disassembly. This foresight minimizes downtime during routine checks or emergency situations, ensuring systems remain operational with minimal disruption. It's a practical consideration that resonates with facilities managers who prioritize long-term reliability over quick fixes.

Furthermore, innovations like lightweight yet durable materials and intuitive installation guides set these valves apart from conventional options. By reducing physical strain on installers and clarifying assembly steps, they prevent common errors that could lead to rework. The result is a smoother, more predictable installation experience that professionals appreciate for its consistency and reduced risk of compliance issues.

Comparing UL FM Gate Valves with Other Fire Protection Systems

When evaluating gate valves for fire protection, UL and FM certifications represent distinct standards that influence performance. UL-listed gate valves are typically designed to meet specific North American safety and reliability criteria, focusing on materials and operational durability under fire conditions. In contrast, some other systems, like European-certified valves or non-listed alternatives, might prioritize different aspects, such as cost-efficiency or compatibility with regional regulations. This comparison highlights how UL FM valves often provide a tailored approach for certain jurisdictions, ensuring compliance with local fire codes while balancing robustness and maintenance needs.

Beyond certification differences, gate valves vary in application across fire protection setups. For instance, UL FM gate valves are commonly integrated into sprinkler systems where precise flow control and leak resistance are critical, outperforming ball valves or butterfly valves in high-pressure scenarios. Other systems, such as deluge or foam-based protection, might rely on different valve types that prioritize rapid activation over fine-tuning. This distinction underscores why choosing UL FM gate valves can enhance reliability in standard water-based systems, whereas alternative valves might suit specialized environments with unique hazards.

In terms of long-term value, UL FM gate valves offer advantages like extended service life and easier inspection, thanks to standardized testing protocols. Compared to non-certified or generic valves, which may degrade faster under harsh conditions, these certified options reduce downtime and repair costs. However, for budget-conscious projects or systems with infrequent use, other valves might suffice, emphasizing that the best choice depends on balancing safety, cost, and specific operational demands in fire protection planning.

Installation Best Practices for UL FM Gate Valves in Diverse Settings

When installing UL FM gate valves across different environments, it's crucial to adapt to site-specific conditions rather than relying on a one-size-fits-all approach. For instance, in industrial settings with high vibration or corrosive elements, ensure valve placements include extra bracing and corrosion-resistant coatings to maintain integrity over time. Outdoor installations demand weatherproofing measures like protective housings to shield against UV exposure and moisture, while indoor setups in confined spaces might prioritize accessibility for future maintenance checks. Always verify that mounting supports align with valve weight and operational stresses, and consider local building codes, which can vary by region—this proactive customization helps prevent premature failures and ensures reliable performance under varying pressures and temperatures.

Another key aspect is integrating UL FM gate valves seamlessly into existing systems, which requires careful attention to piping alignment and flow dynamics. Avoid forcing connections or using mismatched fittings, as this can lead to leaks or reduced efficiency; instead, use flexible adaptors where needed to accommodate thermal expansion or movement. In multi-valve arrangements, such as in fire protection networks, position valves to allow easy isolation during emergencies without disrupting adjacent components. Testing post-installation is non-negotiable—conduct pressure and leak tests under simulated operational conditions to catch any issues early, and document results for compliance with FM Global standards. This hands-on verification step not only boosts safety but also extends valve lifespan by identifying potential weak points before they escalate.

Lastly, personnel training and ongoing upkeep play a significant role in maximizing valve effectiveness. Educate installers on proper handling techniques, like avoiding excessive torque during assembly, and provide clear labeling for valve functions to aid quick identification during inspections. In diverse settings—from commercial buildings to remote facilities—establish a regular maintenance schedule tailored to environmental factors; for example, valves in dusty areas may need more frequent cleaning to prevent clogging. By fostering a culture of diligence and adaptation, you can enhance system resilience and ensure UL FM gate valves perform optimally wherever they're deployed, ultimately supporting long-term operational continuity and safety goals.

Maintenance Tips to Ensure Long-Term Fire Safety Compliance

Keeping up with fire safety isn't just about checking boxes once a year; it's a continuous commitment to vigilance. Think of it like tending to a garden—regular, small actions prevent major issues down the line. For instance, start by creating a maintenance log that tracks every inspection, test, and repair. This log should be detailed, noting dates, findings, and who performed the work. Don't just rely on memory or sticky notes; a documented history not only proves compliance but also helps spot patterns, like a particular exit sign that seems to fail every six months. It's those little details that can make all the difference when an inspector visits or, more importantly, in an emergency.

Another key tip is to go beyond the obvious. Sure, you'll test smoke alarms and fire extinguishers regularly, but how often do you check emergency lighting or fire doors? These components can degrade silently over time. Schedule proactive checks—maybe quarterly for lights and doors—and involve staff in simple visual inspections. For example, train employees to report if a fire door doesn't close properly or if an exit path gets blocked. This builds a culture of safety where everyone plays a part, not just a designated safety officer. Plus, it reduces the risk of surprises during formal audits.

Lastly, adaptability is crucial for long-term compliance. Fire safety standards evolve, so your maintenance plan should too. Stay updated on local regulations and industry best practices by attending workshops or subscribing to safety newsletters. Consider integrating technology, like smart sensors for fire systems that alert you to issues in real-time. By blending routine checks with a forward-thinking approach, you ensure your fire safety measures remain robust and compliant year after year, protecting both property and people without last-minute scrambles.

Innovations and Future Trends in UL FM Gate Valve Solutions

Engineers and industry leaders are looking beyond traditional designs, integrating smart technologies that transform UL FM gate valves from simple flow control devices into active system components. These innovations include embedded sensors for real-time pressure and temperature monitoring, wireless connectivity for remote diagnostics, and predictive maintenance algorithms that alert operators before potential failures. By leveraging data analytics, facilities can optimize valve performance, reduce downtime, and enhance safety, making these solutions integral to modern industrial automation and risk management.

Looking ahead, trends point toward greater sustainability and resilience in valve solutions, with advancements in materials like corrosion-resistant alloys and composite polymers extending product lifespans in harsh environments. Additionally, the rise of modular designs allows for easier customization and faster installation, cutting costs and project timelines. As industries face stricter regulatory standards and climate challenges, UL FM gate valves are evolving to support greener operations, such as by minimizing leakage and improving energy efficiency.

The future will likely see deeper integration with Internet of Things platforms, enabling seamless communication between valves and broader control systems for holistic plant management. This shift not only boosts operational precision but also opens doors to new applications in sectors like renewable energy and water treatment, where reliable flow control is critical. Ultimately, these innovations aim to deliver smarter, more adaptable solutions that meet the dynamic demands of 21st-century infrastructure.

FAQ

Essential features include a robust construction with materials like stainless steel or ductile iron, full-flow design to minimize pressure drop, fire-safe testing compliance per UL/FM standards, anti-static design, and reliable stem sealing to prevent leaks under fire conditions.

The fire rating indicates its ability to maintain operational integrity during a fire. Higher-rated valves are crucial for high-risk areas like chemical plants or refineries, as they must seal tightly even after exposure to flames, preventing flammable fluid leaks and ensuring fire containment.

Yes, many modern designs feature easy maintenance features like bolted bonnets or inline repairability, which allow for quick servicing without removing the entire valve from the pipeline. This minimizes downtime and enhances overall system efficiency.

Common materials include carbon steel for cost-effective durability, stainless steel for corrosion resistance in harsh environments, and ductile iron for strength. These choices ensure longevity and reliability under fire safety and pressure demands.

Gate valves offer a straight-through flow with minimal turbulence, making them ideal for on/off service in high-flow systems during emergencies. Unlike ball valves, they provide a tight metal-to-metal seal that's less prone to degradation under extreme heat, crucial for fire compliance.

Ensure proper alignment with the pipeline to avoid stress, use appropriate gaskets and bolts as per manufacturer specs, conduct pressure testing post-installation, and regularly inspect for signs of wear or leakage to maintain compliance and efficiency.

Avoid undersizing valves for the flow rate, overlooking specific industry standards beyond UL/FM, neglecting environmental factors like temperature extremes, and failing to verify third-party certification documents to ensure genuine compliance.

By providing reliable performance and reduced risk of failure, they lower repair costs and potential fines from non-compliance. Their durability also extends service intervals, cutting replacement expenses over time while enhancing safety.

Conclusion

This comprehensive guide outlines top UL FM gate valve solutions essential for fire safety compliance and efficiency. It begins by exploring the fundamentals of UL FM gate valve design, emphasizing robust construction and materials that meet stringent fire safety standards. Key features enhancing efficiency are highlighted, including durable materials, precise flow control mechanisms, and reliable sealing technologies that minimize water loss and improve system performance. The guide also compares UL FM gate valves to other fire protection systems, demonstrating their advantages in reliability, cost-effectiveness, and ease of integration into various building infrastructures.

Furthermore, the guide details installation best practices for diverse settings, from high-rise buildings to industrial facilities, ensuring optimal placement and operational readiness. Maintenance tips are provided to ensure long-term compliance with fire safety regulations, covering regular inspections, testing, and troubleshooting for sustained efficiency. Innovations and future trends in UL FM gate valve solutions are discussed, such as smart monitoring systems and eco-friendly materials, pointing toward enhanced safety and sustainability. Overall, this guide serves as an ultimate resource for selecting, installing, and maintaining UL FM gate valves to achieve superior fire safety outcomes and operational efficiency.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com