What is a Smart Factory?

2023-10-17

A Smart Factory, also known as a connected factory or digital factory, is a manufacturing facility that utilizes advanced technologies and automation to optimize production processes, improve efficiency, and enhance overall productivity. It is a key component of Industry 4.0, the fourth industrial revolution characterized by the integration of cyber-physical systems, the Internet of Things (IoT), data analytics, and artificial intelligence (AI) in manufacturing.

The concept of a Smart Factory revolves around the interconnectedness and digitization of various components within the manufacturing environment. Here are some key features and elements commonly associated with Smart Factories:

1. Internet of Things (IoT) Integration: Smart Factories utilize IoT devices, sensors, and connectivity to gather real-time data from equipment, machines, and systems. This data enables monitoring, analysis, and decision-making for process optimization and predictive maintenance.

2. Data Analytics and Artificial Intelligence (AI): The collected data is processed and analyzed using advanced analytics techniques and AI algorithms. This allows for actionable insights, predictive capabilities, and intelligent decision-making to optimize production, improve quality, and reduce downtime.

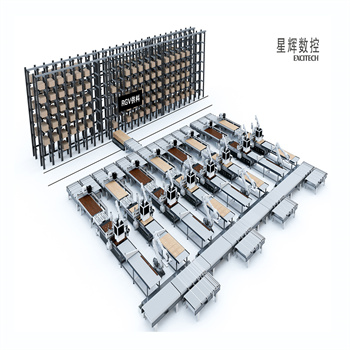

3. Automation and Robotics: Smart Factories employ automation technologies such as robotics, autonomous guided vehicles (AGVs), and automated material handling systems. These technologies can perform repetitive tasks, enhance precision, and increase productivity, while also reducing the risk of human error.

4. Digital Twin: A digital twin is a virtual replica of a physical asset or production process. Smart Factories use digital twins to simulate and optimize manufacturing operations, enabling virtual testing, predictive modeling, and scenario planning to improve efficiency and reduce costs.

5. Integration and Connectivity: Smart Factories integrate various systems, machines, and equipment across the production line. This integration enables seamless communication and coordination between different components, facilitating efficient workflow, resource allocation, and real-time decision-making.

6. Agile Manufacturing: Smart Factories are designed to be flexible and adaptable to changing production needs. They can quickly adjust production schedules, accommodate customization, and respond to market demands in a more agile and efficient manner.

7. Supply Chain Optimization: Smart Factories extend their digital connectivity beyond the factory floor to integrate and optimize the entire supply chain. This includes real-time visibility of inventory, demand forecasting, efficient logistics, and collaborative partnerships with suppliers and customers.

The overarching goal of a Smart Factory is to improve efficiency, productivity, quality, and flexibility in manufacturing operations while reducing costs and waste. By leveraging advanced technologies and data-driven insights, Smart Factories aim to transform traditional manufacturing into a more connected, intelligent, and responsive ecosystem.