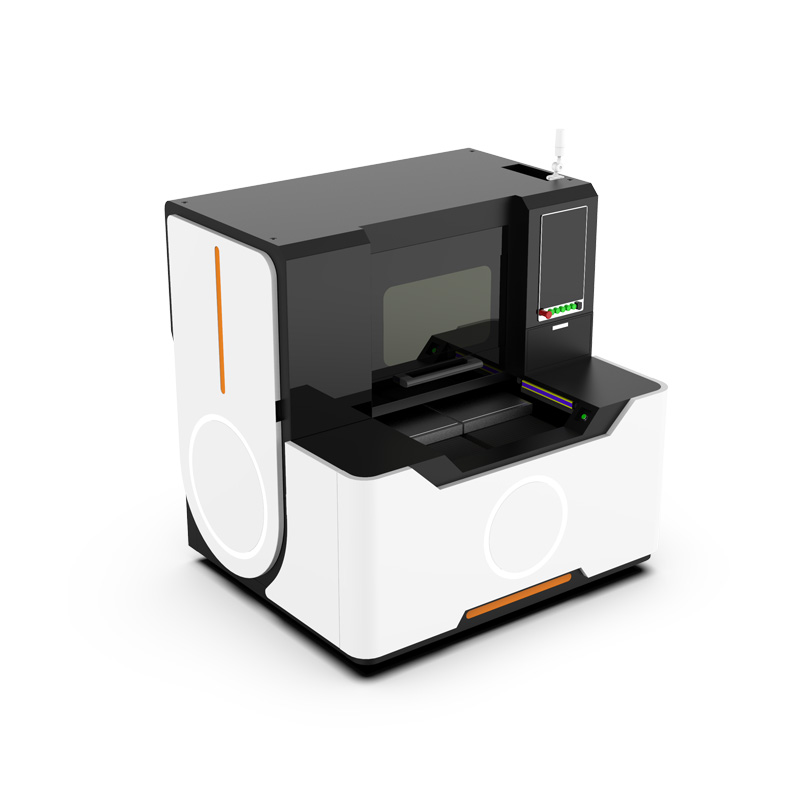

Laser Cutting Machine

A laser cutting machine is a high-precision tool used in various industries for cutting a wide range of materials with the help of a laser beam. It offers a precise and efficient method of cutting through different thicknesses and types of materials, including metals, plastics, wood, fabrics, glass,......

Send Inquiry

Product Description

A laser cutting machine is a high-precision tool used in various industries for cutting a wide range of materials with the help of a laser beam. It offers a precise and efficient method of cutting through different thicknesses and types of materials, including metals, plastics, wood, fabrics, glass, and more.

Here are the key components and working principles of a laser cutting machine:

1. Laser Source: The laser source generates a highly focused and intense beam of light. The most commonly used lasers for cutting applications are CO2 lasers and fiber lasers. CO2 lasers are suitable for cutting non-metal materials, while fiber lasers are ideal for cutting metals.

2. Beam Delivery System: The laser beam is delivered from the laser source to the cutting head through a beam delivery system. This system typically consists of mirrors and lenses that help guide and focus the laser beam.

3. Cutting Head: The cutting head is the component that focuses the laser beam onto the material being cut. It contains a focusing lens that concentrates the laser energy into a small spot to achieve high precision and control.

4. Worktable: The worktable holds the material being cut. It may be a fixed bed or a movable bed, depending on the type of laser cutting machine. Movable beds allow for greater flexibility and the ability to process larger materials.

5. CNC System: Most laser cutting machines are equipped with a CNC (Computer Numerical Control) system. This computerized control system interprets the design data and controls the movement of the laser cutting machine, directing the laser beam along the desired cutting path.

6. Assist Gas System: An assist gas, such as compressed air, nitrogen, or oxygen, is used in laser cutting machines to improve the cutting process. The assist gas helps to blow away molten material and debris from the cutting area, ensuring clean cuts and preventing damage to the focusing lens.

The operation of a laser cutting machine involves the following steps:

1. Design Preparation: The desired shape or pattern to be cut is prepared using computer-aided design (CAD) software. The design file is then transferred to the CNC system of the laser cutting machine.

2. Material Preparation: The material to be cut is securely placed on the worktable. Depending on the machine, the material may need to be clamped or fixed in place to ensure stability during the cutting process.

3. Machine Setup: The operator sets up the laser cutting machine, adjusting parameters such as laser power, cutting speed, and assist gas pressure based on the material and thickness being cut.

4. Cutting Process: Once the setup is complete, the CNC system guides the laser beam along the programmed cutting path. The laser beam melts or vaporizes the material along the cutting line, creating the desired shape or pattern.

5. Finishing and Unloading: After the cutting process is complete, the cut parts or components are removed from the machine. Depending on the application, additional post-processing steps such as cleaning or surface treatment may be required.

Laser cutting machines offer several advantages, including high precision, speed, versatility, and the ability to cut intricate shapes and patterns. They are widely used in industries such as manufacturing, automotive, aerospace, electronics, signage, and many others where precise and efficient cutting is essential.